Product lineup

Hydraulic Die Cutting Machine

-

OP/OPT

Program management makes operation simple, bringing immediate benefits even to beginners.

View more -

OPT

Designed with a lower table than OP Series products, to make work easier.

View more -

OP

Our best-selling hydraulic cutting machine.

View more -

OP Heat Board

Capable of molding and cutting at the same time.

View more -

HP

The upper panel can be dropped for a lower path line, increasing operability even on wide panel surfaces.

View more -

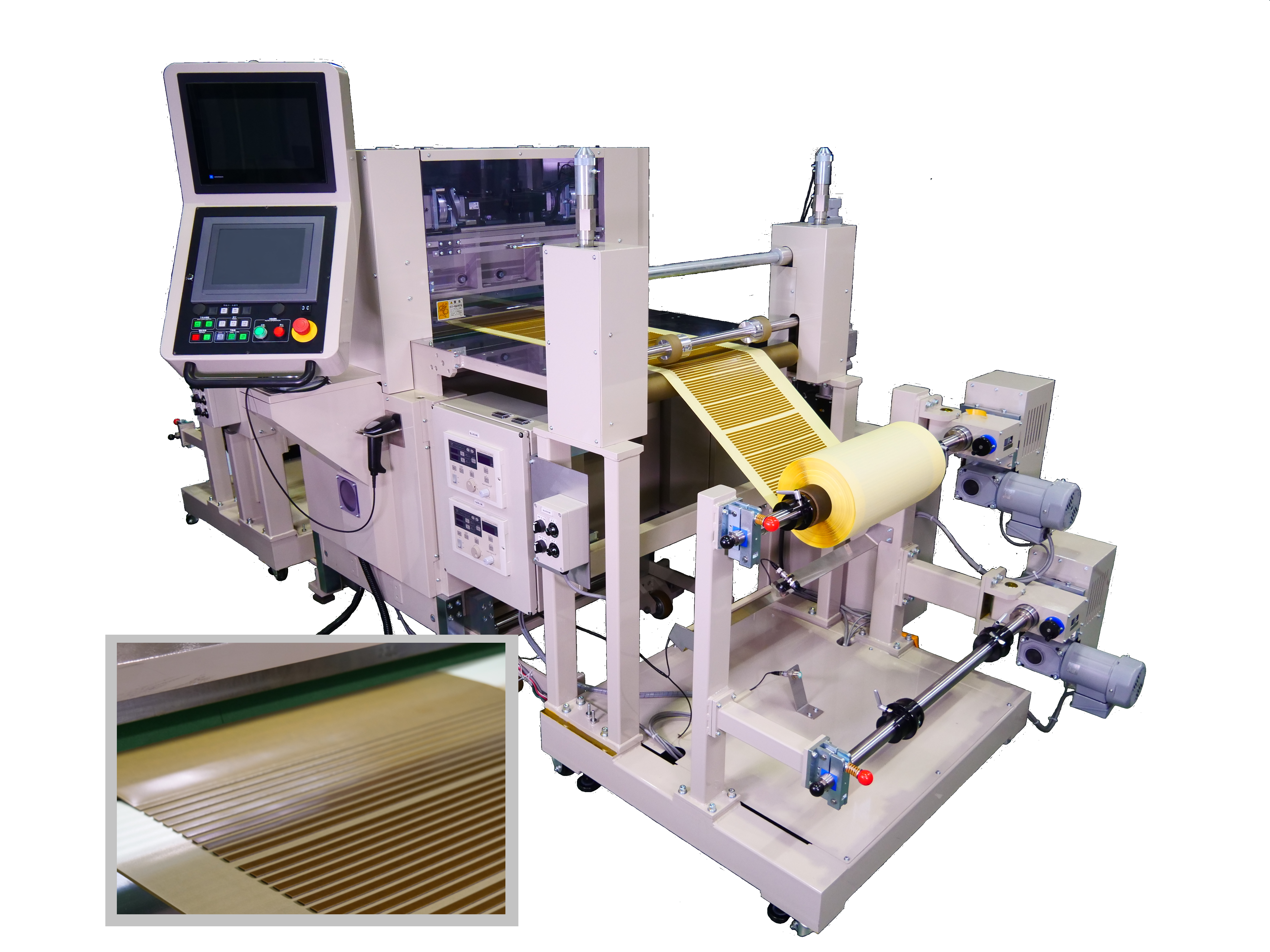

HP-NC

Hydraulic continuous cutting machine that supports various sheet materials, focused on rolled sheets.

View more

NC High Speed Precision Die Cutting Machine

-

MP-SR

High-speed precision continuous cutting machine with a nip roll feed mechanism.

View more -

MP-SL

Our best-selling servo crank cutting machine. Table-type high-speed precision continuous cutting machine.

View more -

MPC-SR

Contains a nip roll feed mechanism, and uses a direct calibration camera for accurate positioning.

View more -

MPC-SL

This table-type machine uses a direct calibration camera for accurate positioning.

View more

NC High-Speed Precision Multi Purpose Cutter

-

ACS-SRN/AC-SRN

A cutter that does not generate material loss and greatly reduces the waste processing process.

View more -

ACS

Airless cutter where all settings can be managed digitally.

View more -

AC-SR

High-speed precision continuous cutter with a nip roll feed mechanism.

View more -

AC-SL

Table-type high-speed precision continuous cutter.

View more -

A

Safety-conscious round blade whole-sheet cutting machine.

View more -

AS

Safety-conscious round blade whole-sheet cutting machine. Capable of fullut and back-cut operations.

View more

Peripheral Equipment

-

Helper robot

This robot automatically moves from material cutting to product gathering, helping to make up for labor shortages.

View more -

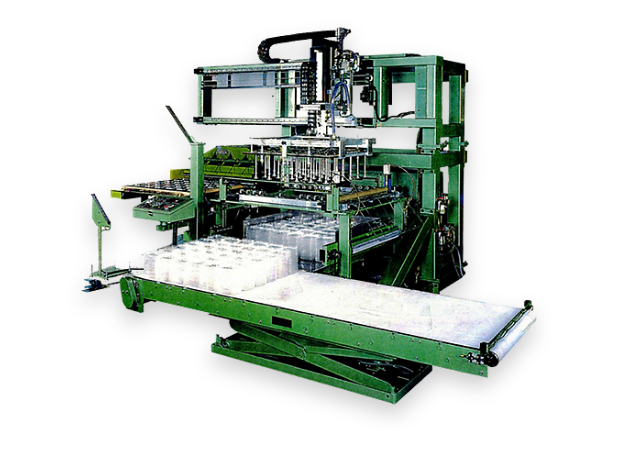

ALS

Automatic transport, unstacking, and stacking of a variety of molded components, to significantly reduce labor.

View more -

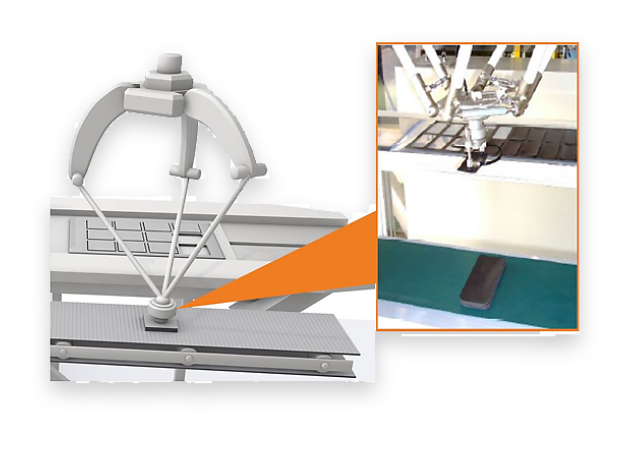

TORI ROBO

The industry's first delta robot, capable of separating and inspecting products at the same time.

View more -

ADC

Capable of automatically supplying blades to the machine, eliminating the need for troublesome blade replacement work.

View more

Useful Item

-

E-plate

Say goodbye to pricey backing boards. Discover the new board that cuts effortlessly with scissors.

View more -

Q Sheet, Q Tape

Micro sucker sheet that can be attached and removed multiple times, and is perfect for securing materials in place.

View more -

RIVEROID

This etching blade provides higher precision than Thomson blades, at a lower cost than an engraving blade.

View more -

ES DIE

This etching blade provides higher precision than Thomson blades, at a lower cost than an engraving blade.

View more -

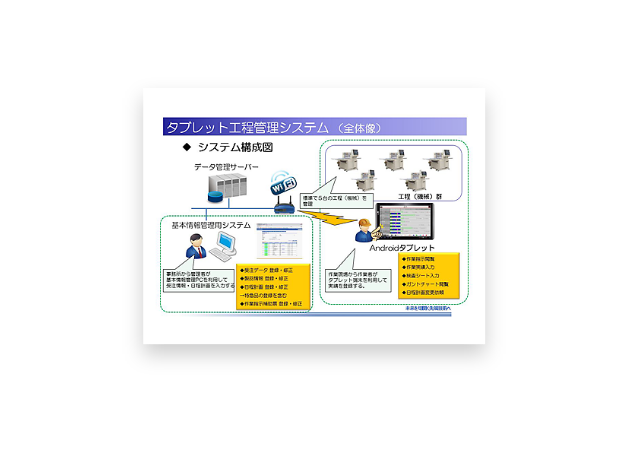

Process management system

This process management system helps to visualize processes and reduce the use of paper.

View more

Company

Overview

- Corporate name

- AKEBONO MACHINE INDUSTRIES CO.,LTD.

- Foundation

- June, 1943

- Capital

- 30,000,000yen

- Corporate representative

- Yuichiro Arai, President

- Banks

-

(Main)Saitama Risona Bank, Gyoda Branch Office

Mizuho Bank, Kumagaya Branch Office

UFJ Bank, Omiya Branch Office - Head Office

-

1-3, Kamatsuka, 1-chome, konosu-city, Saitama-prf. Japan 3690112

Phone +81 48-548-0631

Factory lot area: 6,088m2

Base introduction

-

Head Office

Google Map

Google Map1-1-3, Kamatsuka, kounosu-city, Saitama-prf. Japan 3690112

- TEL

- +81 48-548-0631

-

Honjyo Factory

Google Map

Google MapKodama Industrial Park, Honjyo-city, Saitama-prf. Japan 3670037

- TEL

- +81 495-21-8123

-

Osaka Sales Office

Google Map

Google Map17-18, Toyotsumachi, Suita-city, Osaka-cap. Japan 5640051

- TEL

- +81 6-6192-2511

- oosaka@akebonomc.co.jp

-

Nagoya Liaison Office

Google MapRoom201, 1-3-12, Midori Ichinomiya-city, Aichi-prf. Japan 4910862

- TEL

- +81 586-24-3368

- y.horiguchi@akebonomc.co.jp

-

Akebono Create (ShangHai)

Machine Trade Co., LtdGoogle MapRoom 1404, Building XinYin, No.888 YiShan Road, XuHui, ShangHai China 200233

- TEL

- +86-(21)64320201

- hantao@akebonomc.co.jp